-

430 Sheets & Plates

Typical Composition:

Chromium: 16-18%,

Nickel: <0.75%,

Manganese: <1%,

Silicon: <0.12%,

Phosphorus: 0.040%

Sulfur: 0.030%.Mechanical Properties:

Grade 430 Tensile Strength

(MPa) min483 Yield Strength

0.2% Proof(MPa) min310 Elongation

(% in 50mm) min22 Hardness

Brinell (Max)183 430 SS is used in numerous applications, generally preferred in decorative purposes such as household appliances, metal molding, metal trim, hinges, cabinet hardware, stampings etc.

Common Applications:

Kitchenware- Cooking utensils,Linings for dishwashers,Ovens,Refrigerator

cabinet panels,Stove trim rings and chimney liners

Construction- Gutters and downspouts,Roofing,Siding

Automotive trim and molding

Oil Refinery Equipment

Oil burner and heater parts

Chemical ProcessingWe are one of the most reliable & comprehensive stockholder, supplier & exporter of high quality 430 Stainless Steel Sheets, Plates & Coils.

The sheets procured & supplied/exported by us are from the leading mills across the globe.

Material Origin:

India,Europe,Korea, United States, Thailand, Taiwan, JapanManufacturers:

Acerinox, Aperam, Bahru, Baosteel, DKC, Jindal, Nippon, Outokumpu, POSCO, SAIL,

Thyssenkrupp.We are able to supply cut to size 430 SS sheets & plates (as per your specifications) in any quantities with all the necessary mill test reportss.

430 STAINLESS STEEL SHEETS/PLATES/COILS SPECIFICATIONS:

Standard: ASTM A240

Surface Finish: 2B, 2D, BA, HL, No.4

Size Ranges :Sheets:

Thickness: 0.25mm ~ 6.0mm

Width: 600mm ~ 2000mm

Length: 1000mm ~ 10000mmPlates:

Thickness: 3mm to 100mm

Width: 1000mm to 3000mm

Length: 2438 mm / 3048mm / 6098 mm to 12500 mmCoils:

Thickness: 0.31mm ~ 12.7mm

Width: 1000mm / 1120mm / 1250 / 1525mm / 2000mm

Length: as per your requirement.*(Cut to sizes available as per your requirement.)

Types: Flat bars,Strips,Circle, Ring, Profile

-

Duplex & Super Duplex Bars Wires

It gives double strength to the structure. The Duplex Steel Round Bars give a much higher resistance against corrosion cracking and uniform erosion. These Duplex Steel Round Bars offer higher performance in a lesser expensive way. The chemical, oil and gas technology industries all over the world use these highly resistant Duplex Steel Round Bars.

DUPLEX & SUPER DUPLEX ROUND BAR, RODS

RANGE: DIA 6 MM TO 300 MM (100 MM TO 12000 MM LONG)

FORM: ROUND BAR, SQUARE BAR, FLAT BARS & HEX BAR.

FINISH : BRIGHT BARS, BLACK BARS & FORGED BARS

GRADE: DUPLEX STEELS : 2205, 31803, UNS -S32205, UNS-S31803

SUPER DUPLEX STEEL : 2507, ZERON-100, UNS-S32750, UNS-S32760, UNS-S32550,UNS-S39274

STAINLESS STEEL : 304 / 304L, 321, 347, 316/ 316L / 316Ti, 317 / 317L, 310s- Other grades of Duplex & Super Duplex Bars & Rods

- Duplex Sheets Round bars & Wires

- Super Duplex Round bars & Wires

- Duplex Sheets UNS S31803 Round bars & Wires

- Super Duplex UNS S32205 Round bars & Wires

- Duplex & Super Duplex UNS S32750 Round bars & Wires

-

Fittings

ANSI/ASME fittings and ISO fittings

- Butt weld fittings

- Socket weld fittings

- Threaded fittings

- Threaded fittings

- Outlets

Specifications:

- ASTM A 403WP 304 / 304L / 304H / 316 / 316L / 317 / 317L / 321 / 310 / 347 / 904L

- Others: Monel, Nickel, Inconel, Hastelloy, Copper, Brass, Bronze, Titanium, Tantalum, Bismuth, Aluminium, High Speed Steel, Zinc & Lead

- Types: Elbow, Tee, Reducer, Return Bends, Stub-Ends, Collar & Insert

- Size: 1/4″NB to 32″NB. (Seamless and Welded) wall thickness Schedule 5S to schedule XXS

-

309 / 309S Sheets & Plates

Typical Composition:

Chromium 23% max

Nickel 14% max

Manganese 2% max

Silicon 1% max

Carbon 0.20% max

Phosphorous 0.045% max

Sulfur 0.030% max

Iron Balance309 stainless steel has more corrosion & temperature resistance and strength compared to 304 grade stainless steel.

Common Applications:Boiler baffles

Fire box sheets

As filler metal when welding dissimilar steels

Auto exhaust part

Furnace components

Other high temperature containers

Heating elements

Refinery and chemical processing equipment

Kiln liners309 Steel Sheets available with mill test certificate related to its marking on it.

-

Duplex & Super Duplex pipes tubes

On account of the above mentioned properties, the duplex-super-duplex-pipe-tubes find extensive use in the applications where there is requirement of good impact toughness, high intensity, high pressure work, ability to avoid crack and patch, greater corrosion resistance compared to the standard duplex grades such as:

- Petrochemical

- Geothermal

- Oil & Gas

- LNG

- Pharmaceutical

- Desalination of water

- Solar power

- Mining

- Nuclear power

- Biomass

RANGE :

TUBING SIZE : 1/2″ OD TO 4″ OD (IN ALL THICKNESS)

NOMINAL BORE (NB) SIZES : 1/2″NB TO 48″ NB (IN ALL THICKNESS)QUALITY :

DUPLEX & SUPER DUPLEX STEEL

UNS S31803, S32205 (2205),S32750 (2507), S32760 (Z-100)

S32900 (329), S32304, F-51, F-53, F-54, F-55 & F-60 & HIGH NICKEL ALLOYSTYPE :

WELDED (ERW) PIPES, FEBRICATED PIPES & SEAMLESS PIPESEND :

PLAIN END, BEVELLED END & THREADED ENDSHAPES :

ROUND & SQUAREVALUE ADDED SERVICES :

- Annealed

- Anodising

- Bending

- Casting

- Cutting

- Centreless Grinding (Cg)

- Draw & Expansion

- Drilling

- Electroplating

- Fabricate (With Radiography)

- Heat Treatment (Hardening & Tempering)

- Machining (Cnc)

- Minor Fabrication

- Pickled

- Polish (Electro & Commercial)

- Sand Blasting

- Threading (As Per Guage)

- Welding

TEST CERTIFICATION :

Our Materials Are Tested To Relevant Standard And Wherever Possible We Give Original / Copy Of Test Certificate With Heat Number As Well As Govt. Approved Laboratories Test Certificate Can Also Be Provided. We Supply the Material under Inspection of Any Third Party Inspection Agency as per the Client’s Requirements Such As :

1) Bv- Bureau VERITAS Industrial Services (India) Pvt. Ltd

2) Lloyds Inspection Agency

3) Rina

4) Irs – International Register Of Shipping (Irs)

5) Dnv – Det Norske Veritas

6) Tcs – Tata Consultancy Services

7) Tuv India -

Incoloy alloy

Incoloy Availability

Calico Metal supplies Incoloy 800, 800H/HT> and 825 in the form of plate, sheet, strip, bar, wire, pipe, tubing, pipe fittings, and flanges.

What are the Characteristics of Incoloy?

- Good corrosion resistance in aqueous environments

- Excellent strength resistance in high-temperature settings

- Excellent oxidation and carburization resistance in high-temperature settings

- Good creep-rupture strength

- Ease of fabrication

-

Pipes & Tubes

A-312, A-335 Seamless Pipe, Welded Pipe, Seamless Pipe, ERW Pipe Supplier

Sr. No.

Material Size Sch.

Specification

Manufacturer 1 Seamless Pipe 15 NB

To

300 NBSch. 5s

Sch. 10s

Sch. 40s

Sch. 80s

Sch. 160s

Sch. XXSA-312 Imported

Choksi

Remi &

Ratnamani2 Welded (ERW) Pipe 15 NB

To

300 NBSch. 5s

Sch. 10

Sch. 40s &

Sch. 80sA-312 Remi

Ratnamani

Vishal

Suraj

C.D. Prakash

Heavy

Imported Etc.3 Welded (ERW) Pipe 150 NB

To

600 NBSch. 5s

Sch. 10s

Sch. 40s &

Sch. 80sA-358 Fabricated at Famous

Prakash

Vishal (with Radiography)Note : Grade

: TP 304, TP 304H, TP 304L, TP 304LN, TP 316, TP 316H, TP 316L, TP 316LN, TP TP 316Ti, TP 309, TP 310, TP 317L, TP 321, TP 347, TP 409, TP 410, TP 420, TP 430, TP 446,

TP 202 Etc.Special Pipes : Fabricated Pipe (with radiography) In Form of : Round, Square, Rectangle, Oval, Coil, Flexible Pipe, Shaft, ‘U’ Shape, Hydraulic pipe etc. In Length of : Standard & Cut length Value Added Service : Draw & Expansion as per required Size & Length

Polish (Electro & Commercial) Heat Treatment

Bending

Annealed & Pickled

Sand Blasting

Machining Etc.Test Certificate : Manufacturer Test Certificate Laboratory Test Certificate from Govt. Approved Lab.

Under Third Party InspectionSpecialize : Fabricated Pipe, Square & Rectangle & Other Odd Size Carbon Steel Pipes

Sr. No.

Material Size Sch. & Swg.

Specification

Manufacturer 1 Seamless Pipe 15 NB to

300 NBSch. 40s To

Sch. XXsA-335

SeamlessISMT / Kalyani / Imported with LRS & IBR Test Certificate Note : Pipe in Grade

: ASTM A 335 –P1, P2, P5, P9, P11, P12, P21, P22 & P91 Etc. (with IBR Test Certificate) In Length of : Standard Double & In Cut length also. Value Added Service : Draw & Expansion as per required Size & Length, Heat Treatment, Bending

Annealed, Machining Etc.Test Certificate : Manufacturer Test Certificate, IBR Test Certificate ,Laboratory Test Certificate from Govt. Approved Lab. & Under Third Party Inspection Mild Steel & Galvanised Pipes

Sr. No.

Material Size Sch. & Swg.

Specification

Manufacturer 1 Mild Steel (M. S.) & G. I. 15 NB to

150 NB‘A’ Class

‘B’ Class

‘C’ ClassIS 1239 Tata

Zenith

Jindal

Mukat

Lloyds

Lalit Profiles Etc.200 NB to

500 NB4.85 mm

to

12.7 mm Thk.IS 3589

(Fe 330, Fe 410)Note : In Form of

: Round, Square, Rectangle Special Pipes : Standard & Cut length In Length of : Standard & Cut length Value Added Service : Draw & Expansion as per required Size & Length Galvanizing, Etc. Test Certificate : Manufacturer Test Certificate, Laboratory Test Certificate from Govt. Approved Lab. & Under Third Party Inspection Specialize : Square Tube, Rectangle Tube & Odd Size Nickel Alloys Pipes

Sr. No.

Material Size Sch. & Swg.

Specification

Manufacturer 1 Cupro Nickel

Hastelloy

Nickel

Monel

Inconel

Alloy 20

Duplex15 NB to 150 NB Sch. 10

Sch. 40

Sch. 80 Etc.IS

BS

ASTM

UNSImported & Indian Mfg. Note : Nickel Alloy in Grade

: Cupro Nickel, Hastelloy, Nickel, Monel , Inconel , Incolloy Alloy 20, Duplex Steel, SS 904L, Etc.

90/10, 70/30, 66/30/2/2 , C-4, C-22, C276, B-2 , 200 / 201 / 205

400 & K500, 600, 601, 625 & 825 ,800, 800HIn Form of : Round , Etc. In Length of : Standard & Cut length Value Added Service : Draw & Expansion as per required Size & Length, Heat Treatment, Annealed

Machining Etc.Test Certificate : Manufacturer Test Certificate Laboratory Test Certificate from Govt. Approved Lab. & Under Third Party Inspection Specialize : Cupro Nickel Tube Non Ferrous Pipes

Sr. No.

Material Size Swg. Specification Manufacturer 1 Copper

Brass

Aluminium

Phosphorus Bronze

Gun Metal

Lead2 mm OD to

152 mm OD16 Swg.

14 Swg.,

12 Swg.

10 Swg.16 Swg.

14 Swg.,

12 Swg.

10 Swg.IS

BS

ASTMIndian Note : Copper Brass Lead In Grade : Dow & PVC Coated 63/37, 70/30, Admiralty Brass, Aluminium Brass

(99.95 to 99.99)Special Tube : Referigeration Tubes, Annealed Tube Etc. In Form of : Straight, Round, Coil, Shaft, Bush, U’ Shape Etc. In Length of : Standard length & In Cut length also. Test Certificate : Laboratory Test Certificate from Govt. Approved Lab. &

Under Third Party Inspection

with Excise Gate Pass to avail Modvat benefit.Value Added Service : Draw & Expansion as per required Size & Length

Bending

Anneling & Pickled Etc.Hardness : Soft, Hard, Half Hard, Quarter Hard Etc. Specialize : De-oxidize Copper Tube (99.99% Cu) & Admiralty Brass Tube NOTE : Non ferrous pipe come in od form . Other grades of Stainless Steel Pipes

Seamless Pipes Welded Pipes ERW Pipes Carbon Steel Pipes Mild Steel & Galvanised Pipes Nickel Alloys Pipes Non Ferrous Pipes -

904 / 904L Sheets & Plates

It gives good resistance to stress corrosion cracking and crevice corrosion. Grade 904L stainless steel is non-magnetic and provides superior form ability, toughness as well as weld ability.

Test Certificate: All 904L plates available with its mill test certificate related to its markings.

Typical Composition:

Chromium: 19-23%

Nickel: 23-28%

Molybdenum: 4-5%

Copper: 1-2%

Manganese: 2% max

Silicon: 1% max

Carbon: 0.02% max

Phosphorous: 0.045% max

Sulfur: 0.035%

Iron: Balance904L grade is useful in instrumentation & control tubing applications.

Typical Applications:

Utility scrubber assemblies

Heat exchangers

Acetic, sulphuric & phosphoric acid processing plants

Gas washing

Acid and fertilizer production equipment

Condenser tubes

Seawater cooling equipments -

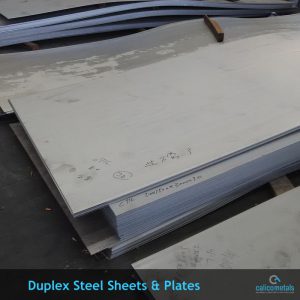

duplex & super duplex Steel Plates

There are number of qualities in the duplex and super duplex sheet/ plates offered by us such as good workability and weldability, high strength, combination of ferritic and austenitic mixture properties, low thermal expansion rate etc. On account of these qualities, the duplex and super duplex sheets/plates are extensively used in variety of applications such as:

- Heat exchangers

- Oil field piping

- Food process equipment

- Sea water equipments

- Chemical process vessels

- Petrochemical equipments

- Bleach washers

- Pulp mill digesters

- Chip presteaming vessels

Duplex & Super Duplex Steel Plates

Range :

5mm To 100mm thick in 1000 mm To 2500mm width & 2500 mm to 12500 mm Length available with Nace MR 01-75.Types :

Sheet, Plates, Coils, Flat, Strips, Profile, Blank, Circle, Ring etc.MATERIALS

Duplex & Super Duplex Steel Plates

UNS S31803, S32205, S32750, S32760

Duplex & Super Duplex Steel Sheets

Range :

1 mm To 3 mm thick in 1000 mm to 2500 mm width & 2500 mm to 12500 mm Length available with NACE MR 01-75.Types :

Sheet, Plates, Coils, Flat, Strips, Profile, Blank, Circle, Ring etc.MATERIALS :

Duplex & Super Duplex Steel Sheets

UNS S31803, S32205, S32750, S32760

-

Monel Alloys

There are number of characteristics in Monel alloys that make them very useful such as great resistance to seawater, great resistance to stress corrosion cracking, resistance to hydrofluoric and hydrochloric acids, superb resistance against alkaline and neutral salt, great resistance to alkalis etc. on account of these characteristics, the monel alloys find extensive use in the applications such as hydrocarbon and chemical processing equipment, freshwater and gasoline tanks, de-aerating heaters, marine engineering, crude petroleum stills, distillation towers of crude oil, heat exchangers, chlorinated solvents, valves, shafts, pumps, fasteners, fittings etc.

Manufacturer of Monel Alloy Rods, Bars & Wires

Monel round bars offered by Calico Metal are exceedingly tough and consumption safe, made of Monel400. Keeping in mind the end goal to meet the requests of our household and global customers, they come in alternative of fluctuated measurements, lengths and thickness. Our scope of monel round bars are accessible in diverse grades.

Specification

Standard ASTM / ASME SB 164 Grades Monel 400, Monel k500 Range 5 mm dia To 500 mm dia in 100 mm TO 6000 mm Length Manufacturer of Monel Alloy Plates & Sheets

Calico Metal offers an extensive variety of Monel Sheets and Plates that discovers application in different commercial enterprises over the globe. Made from quality crude material, these monel plates and monel sheets are referred to for its one of a kind elements, for example, tight resilience, smooth surface and uniform mechanical properties.

Specification

Standard ASTM / ASME SB 127 Grades Monel 400, Monel k500 Monel Sheets Thickness 1.5mm to 4mm Monel Plates Thickness 5mm to 150mm Value Added Service

- Heat treatment

- Annealed & pickling

- Rolling, cutting, bending, forging, minor fabrication, etc.

Manufacturer of Monel Alloy Pipes & Tubes

CalicoMetals offers an extensive variety of monel pipes that are known for their phenomenal execution. These pipes are utilized as a part of the soda pop industry on the grounds that it’s harmless to human body. These pipes have high resistance to temperature, with the goal that it can be utilized for transportation of boiling hot water, substance and gas. A percentage of the particulars are as per the following:

Specification

Grades Monel 400, Monel k500 Types Seamless / ERW / Welded/ Fabricated Form Round, Square, Rectangular, Hydraulic etc. Length Single Random, Double Random & Cut Length End Plain End, Beveled End, Threaded Applications

- Hot Dipped Galvanizing

- Epoxy & Fbe Coating

- Electro Polish

- Draw & Expansion

Manufacturer of Monel Alloy Flanges

CalicoMetals are providing a subjective scope of monel flanges which are accessible in different structures and models. These flanges are accessible in diverse sizes and are in consistence with universal norms. We offer these flanges in different particulars and in this way are requested in both residential and universal markets. We offer these flanges at business sector leading costs.

Specification

Grades Monel 400, Monel k500 Range 1/2″ NB to 60″ NB Types Socket Weld, Slip On, Blind, Lapped, Screwed, Weld Neck, Long Weld Neck, Reducing, Spectacle, Ring Joint Features

- Durability

- Corrosion resistance

- Dimensional accuracy

- High strength

- Chemical resistance

- Excellent finish

Manufacturer of Monel Alloy Buttweld Fittings

CalicoMetals is occupied with offering an extensive variety of monel fittings that are built with exactness plans and as per most recent innovation by specialists work force. Meeting the assorted needs of diverse businesses these fittings are accessible in altered determinations at most competitive rates. These fittings are accessible according to the accompanying details:-

Specification

Application

- Petrochemicals Plants

- Chemical Plants

- Industrial Machinery

- Power Industry

- Government Companies

Manufacturer of Monel Alloy Forged Fittings

CalicoMetals being a quality driven association, we offer astounding Monel Forged Fittings. The extent is acclaimed and acknowledged over the globe for its quality and exact outline. They are made utilizing high review crude materials obtained from guaranteed merchants. Our reach incorporates Monel Forged Elbow, Monel Forged Tee, Monel Union, Monel Cross, Monel Swage Nipple, Monel Plug and Monel Bushing

Specification

Grades Monel 400, Monel k500 Types Seamless / ERW / Welded/ Fabricated Form Round, Square, Rectangular, Hydraulic etc. Length Single Random, Double Random & Cut Length End Plain End, Beveled End, Threaded Application

- Petrochemicals Plants

- Chemical Plants

- Industrial Machinery

- Power Industry

- Government Companies

Manufacturer of Monel Alloy Fasteners

CalicoMetals has monel fasteners that are composed with most recent innovation and upgraded hardware, which brings about superior scope of levelers. These levelers are accessible in distinctive determinations at most focused costs. These are accessible in Monel 400, Monel 500 evaluations. Our monel fasteners are accessible in shifting thickness of 0.1 mm, 0.2mm, and so on with diverse details.

Specification

Grades Monel 400, Monel k500 Range 1/2″ NB to 60″ NB Types Socket Weld, Slip On, Blind, Lapped, Screwed, Weld Neck, Long Weld Neck, Reducing, Spectacle, Ring Joint Features

- Optimum strength

- Corrosion resistance

- Long service life

- Fine finish

-

Duplex & Super Duplex Fittings

Our products ensure high pressure sustainability as they are tested under the highest of pressures and are as per the international standards. As compared to ferrtic and austentic steels, the duplex and super duplex fittings offer higher strength and range of corrosion resistance properties. The duplex and super duplex fittings are used across different industries as they are safe for a vast number of applications such as:

- Heat exchangers

- Shipbuilding

- Pulp and paper

- Marine construction

- Pipe systems in chemical tankers

- Blast walls on the offshore platforms.

RANGE :

1/2”NB TO 24”NB IN SCH 5 TO SCH XXSFORM :

ELBOW IN LONG & SHORT RADIUS IN 45DEG, 90 DEG, 180DEG.

EQUAL, UNEQUAL TEE & BERRED TEE

CAPS & CROSSES

LONG & SHORT STUB END

SWAGE NIPPLE & BARREL NIPPLEQUALITY :

DUPLEX & SUPER DUPLEX STEEL

UNS S31803, S32205 (2205),S32750 (2507), S32760 (Z-100)

S32900 (329), S32304, F-51, F-53, F-54, F-55 & F-60 & HIGH NICKEL ALLOYSTYPE :

WELDED (ERW, FEBRICATED & SEAMLESSDIMENTIONAL STANDARDS :

ANSI B16.9SCHEDULES :

Sch 5 to Sch XXS (special wall thicknesses on request)SIZE RANGE :

½” to 80” NB -

Angle, Channel & Flats

- Material :Stainless Steel

- Grade :202, 304, 304L, 316, 316L, 317L, 321, 316 Ti, 309, 310, 904L, 410, 420, 430, 431, etc.

- Standard :ASTM / ASME A/SA 240

- Form :Roll-formed metal

- Angle :Varied, most commonly 90 degree

- Leg :Two of same length

- Size :3 / 4/5 / 6 x 25 x 25, 3 / 4/5 / 6 x 30 x 30

3 / 4/5 / 6/7 x 40 x 40, 4 / 5/6 / 7 x 50 x 50

4 / 5/6 / 7/8 x 60 x 60, 5 / 6/7 / 8/9 x 70 x 70

6 / 7/8 / 9/10 x 75 x 75, 6 / 7/8 / 9/10 / 11 / 12 x 80 x 80

7 / 8/9 / 10 / 11 / 12 x 100 x 100

-

Stainless Steel Circles

Grade :Stainless Steel : 304, 304l, 316, 316l, 310, 317l, 321 Thickness :1 Mm To 100 Mm Diameter :Upto 2000 Mm Cutting :Plazma & Machined Cut Do Ask For Stainless Steel 321 / 347 / 304 / 304 L /316 / 316 Ti/316 L Plates Ready Stock Prime

With TcApplications :

Typical applications include : - • Food processing equipment.

- • Kitchen benches, sinks, troughs, equipment and appliances

- • Chemical containers, including for transport

- • Heat Exchangers.

- • Fabrication industries.

- • Heavy machinery industries.

- • Pressure vessels.

Other grades of Stainless Steel Circles

Stainless Steel 304 / 304l Circles Stainless Steel 310 / 310S Circles Stainless Steel 316 / 316L Circles Stainless Steel 321 / 321H Circles Stainless Steel 347 / 347H Circles Stainless Steel 410 Circles -

347 / 347H Stainless Steel

Typical Composition:

Chromium: 17% to 19%

Nickel: 9% to 13% max

Silicon: 0.75% max

Carbon: 0.08% max

Phosphorus: 0.045% max

Sulfur: 0.030% max

Manganese 2.00% max

Columbium & 10x(C+N) min-1.00% max

Tantalum:

Iron: Balance347H stainless steel is the higher carbon version (0.04 to 0.10%)of 347 ss. It provides improved creep resistance and higher strength at temperatures above 537°C.

Typical Composition of 347H:

Chromium: 17% to 19%

Nickel: 9% to 13% max

Silicon: 0.75% max

Carbon: 0.04% min-0.10% max

Phosphorus: 0.045% max

Sulfur: 0.030% max

Manganese 2.00% max

Columbium & 8 x(C+N) min-1.00% max

Tantalum:

Iron: BalanceDue to its high resistance to continuing heat and corrosion it is recommended for power generation, chemical processing and other high heat applications.

Common Applications:Heavy duty exhaust systems

Chemical processes with high temperatures

Heat exchanger tubes

Aerospace components

High temperature & pressure steam pipes

Oil Refining equipment

Boiler tubes

Radiant heaters -

202 / JT Sheets & Plates

Typical Composition:

Chromium:17-19%

Nickel:4-6%

Manganese:7.5-10% max

Silicon:1% max

Nitrogen:0.25% max

Phosphorus:0.060% max

Sulfur:0.03% max

Carbon:0.15% maxMechanical Properties:

Grade 202 Tensile Strength

(MPa) min515 Yield Strength

0.2% Proof(MPa) min275 Elongation

(% in 50.8mm) min40 Hardness

Rockwell HRB max.95 We are one of the most reliable & comprehensive stockholder, supplier & exporter of high quality 202 SS Sheets, Plates & Coils.

The sheets procured & supplied/exported by us are from the leading mills across the globe.

Material Origin:

India,Europe,Korea, United States, Thailand, Taiwan, JapanManufacturers:

Acerinox, Aperam, Bahru, Baosteel, DKC, Jindal, Nippon, Outokumpu, POSCO, SAIL,Thyssenkrupp.We are able to supply cut to size 202 SS sheets & plates (as per your specifications) in any quantities with all the necessary mill test reports.

202 STAINLESS STEEL SHEETS / PLATES /COILS SPECIFICATIONS:

Standard: ASTM A240

Surface Finish: 2B, 2D, BA, HL, No.4

Size Ranges :Sheets:

Thickness: 0.25mm ~ 6.0mm

Width: 600mm ~ 2000mm

Length: 1000mm ~ 10000mmPlates:

Thickness: 3mm to 100mm

Width: 1000mm to 3000mm

Length: 2438 mm / 3048mm / 6098 mm to 12500 mmCoils:

Thickness: 0.31mm ~ 12.7mm

Width: 1000mm / 1120mm / 1250 / 1525mm / 2000mm

Length: as per your requirement.*(Cut to sizes available as per your requirement.)

Types: Flat bars,Strips,Circle, Ring, Profile

-

Titanium Alloys

Specification

Standard GB / T 3621 -44 ASTMB 265 Grades Grade 1, Grade 2, Grade 3, Grade 4, Grade 5, Grade 7, Grade 9, Grade 23 Value Added Service

- Heat treatment

- Annealed & pickling

- Rolling, cutting, bending, forging, minor fabrication, etc.

Manufacturer of Titanium Alloy Pipes & Tubes

Calico metal offers an extensive variety of Titanium Pipes that are made of subjective crude material acquired from solid merchants. Known for its excellent, solidness and consumption resistance, these titanium pipes are broadly utilized as a part of different commercial ventures over the globe.

Specification

Grades Grade 1, Grade 2, Grade 3, Grade 4, Grade 5, Grade 7, Grade 9, Grade 23 Types Seamless / ERW / Welded/ Fabricated Range 15 NB UP TO 600 NB IN SCH 5S, 10S, 10, 20, 40S, 40, STD, 60, 80S, 80, XS, 100, 120, 140, 160 etc. Form Round, Square, Rectangular, Hydraulic etc. Length Single Random, Double Random & Cut Length End Plain End, Beveled End, Threaded Applications

- Hot Dipped Galvanizing

- Epoxy & Fbe Coating

- Electro Polish

- Draw & Expansion

Manufacturer of Titanium Alloy Flanges

Calico metal create and supply Titanium Alloy Flanges in models like GB, ANSI, ASME, API, JIS, and BS. These titanium amalgam flanges are accessible in differed sizes according to the prerequisite of different application zones like petro-substance venture, pipe designing and open machines. We pack and offer these flanges utilizing wooden cases or according to the necessity of our customers.

Specification

Standard ASTM, ASME, API, AISI, BS, ANSI, DIN, JIS, MSSP, NACE Grades Grade 1, Grade 2, Grade 3, Grade 4, Grade 5, Grade 7, Grade 9, Grade 23 Range 15 NB up to 1500 NB in 150 LBS, 300 LBS, 600 LBS, 900 LBS, 1500 LBS, 2500 LBS available with NACE MR 01-75 Types Socket Weld, Slip On, Blind, Lapped, Screwed, Weld Neck, Long Weld Neck, Reducing, Spectacle, Ring Joint Features

- Durability

- Corrosion resistance

- Dimensional accuracy

- High strength

- Excellent finish

Manufacturer of Titanium Alloy Buttweld Fittings

Calico metal gives an extensive variety of value titanium fittings that are fabricated from quality checked components. Known for its fantastic and strength, these titanium buttweld fittings are broadly utilized as a part of different businesses over the globe.

Specification

Grades Grade 1, Grade 2, Grade 3, Grade 4, Grade 5, Grade 7, Grade 9, Grade 23 Range 15 NB To 600 NB in Sch.:5,10,20,40,80,120,160,XS, XXS. Types Bend (Long & Short) , Elbow (180 Deg., 90 Deg. & 45 Deg.) , Tee (Equal & Unequal) , Reducer (Concentric & Eccentric) , CAP, Stub end (Long &Short) , Nipple (Barrel) Application

- Petrochemicals Plants

- Chemical Plants

- Industrial Machinery

- Power Industry

- Government Companies

Manufacturer of Titanium Alloy Forged Fittings

Mukesh Steel India has a scope of Titanium Forged Fittings are planned and built to extremely intense resiliences under strict quality control strategies. These titanium Forged fittings are made to give release free associations with concoction, handling plants, oil, gas, petrochemical and force era commercial enterprises.

Specification

Grades Grade 1, Grade 2, Grade 3, Grade 4, Grade 5, Grade 7, Grade 9, Grade 23 Size 1/2″ NB to 4″ NB Types

- Titanium Union

- Titanium Coupling

- Titanium Full Coupling

- Titanium Cross

- Titanium Forged Elbow

- Titanium Hex Nipple

- Titanium Plug

- Titanium Bushing

- Titanium Boss

- Titanium Insert

- Titanium Adapter

- Titanium Socket

- Titanium Forged Tee

- Titanium Olets

- Titanium Weldolet

- Titanium Sockolet

- Titanium Elbowlet

- Titanium Thredolet

- Titanium Nipolet

- Titanium Latrolet

- Titanium Sweepolet

- Titanium Half Coupling

Application

- Petrochemicals Plants

- Chemical Plants

- Industrial Machinery

- Power Industry

- Government Companies

Manufacturer of Titanium Alloy Fasteners

Calico metal has Titanium Fasteners and its alloy machining segments are broadly utilized as a part of a wide range of machines, for example, therapeutic hardware and petrochemical gear, and so forth. We supply an assortment of Titanium machining parts, for example, pipe fittings, flanges and fasteners, and so on.. We can likewise offer the products as per customers drawings.

Specification

Grades Grade 1, Grade 2, Grade 3, Grade 4, Grade 5, Grade 7, Grade 9, Grade 23 Types Bolts Stud Bolts, Hex Head Bolts, Socket Hexagon Head Screw Anchor Bolts, U-Bolts, J Bolts, Mushroom Head Square Neck Bolts , T- Head Bolts , Wing Screw , Eye Bolt , Eye Bolt, Foundation Bolts, Structural Bolts. Applications

Titanium fasteners can be used in racing industries such as racing motorcycles and cars, sailing boats and medical equipment, etc.

Manufacturer of Titanium Alloy Round Bar

Titanium round bar is an extremely prevalent go-to for some products. It requires an a great deal more computerized procedure to make than plate and piece, which still include a manual procedure. Round bar fits a large number of products, from clasp to adornments.

Titanium round bar is accessible in a large portion of the right around 40 grades, with the most well-known being evaluation 5 and grade 2. The restorative field frequently utilizes little distance across round bar for body implantable clasp and dental machines. Round bar is produced using little measurements of wire for welding, as far as possible up to bigger breadths, (for example, the 14″ distance across), utilized for grip and flywheelSpecification

Grades 6AL4V, 5AL/2.5SN, 6AL/6V/2SN, 6AL4V ELI, 6AL/2SN/4ZR/2MO, 8AL/1MO/1V, 6AL4V STA, 6AL/2SN/4ZR/6MO, CP, OTHER Sizes Diameter (inches)0.125 in. through 4.5 in.

Diameter (millimeters)

3.175 mm through 381 mmFeatures

- Durable finish standards

- Strong structure

- Long life

- Heat resistance

- Precisely designed

-

317 / 317L Sheets & Plates

Typical Composition of 317 SS:

Chromium: 19% max

Nickel: 13% max

Molybdenum: 3.50% max

Manganese: 2% max

Silicon: 1% max max

Carbon: 0.080% max

Phosphorous: 0.045% max

Sulfur: 0.030% max

Iron: Balance317L Stainless Steel Sheets are the low carbon austenitic stainless steel sheets with additions of chromium, nickel and molybdenum for increased corrosion resistance and enhanced resistance to chemical attack of sulfurous, acetic, citric, and tartaric acids. 317L SS also gives good resistance to sensitization at elevated temperatures.

Typical Composition of 317L SS:

Chromium: 18-20% max

Nickel: 11-15% max

Molybdenum: 3-4% max

Manganese: 2% max

Silicon: 1% max

Phosphorous: 0.045% max

Carbon: 0.03% max

Sulfur: 0.03% max

Iron: BalanceMechanical Properties:

Grade 317 317L Tensile Strength

(MPa) min620 595 Yield Strength

0.2% Proof(MPa) min275 260 Elongation

(% in 50mm) min45 55 Hardness

Rockwell B85 85 It is commonly used in handling of bleaching solutions, sulfur & chemical compounds.

Other Applications of 317 /317L SS Sheets/Plate/Coils:Textile equipment

Chemical equipment

Pulp & paper equipment’s

Food processing

Fossil condensersWe are one of the most reliable & comprehensive stockholder, supplier & exporter of high quality 317 SS Sheets, 317L SS Sheets, Plates & Coils.

The sheets procured & supplied/exported by us are from the leading mills across the globe.

Material Origin:

India,Europe,Korea, United States, Thailand, Taiwan, JapanManufacturers:

Acerinox, Aperam, Bahru, Baosteel, DKC, Jindal, Nippon, Outokumpu, POSCO, SAIL,

Thyssenkrupp.We are able to supply cut to size 317 / 317L SS sheets & plates (as per your specifications) in any quantities with all the necessary mill test reports.

317 / 317L STAINLESS STEEL SHEETS/PLATES/COILS SPECIFICATIONS:

Standard: ASTM A240 317 / 317L

Surface Finish: 2B, HR No.1*(Cut to sizes available as per your requirement.)

Types: Flat bars, Strips, Circle, Ring, Profile.

-

Hast Alloy

Manufacturer of Hastelloy Alloy Rods, Bars & Wires

calico Metal offer an extensive variety of Hastelloy Rod, Bars and Wires that are produced under the direction of our specialists and as per industry characterized parameters. These are gotten to at a financially savvy cost. Moreover, our reach discovers enormous interest in the aggressive business sector for strength, elite and dimensional precision.

Specification

Grades Hastelloy C-22, Hastelloy C-276, Hastelloy C-2000 Types Hastelloy Round Bar , Hastelloy Bright Bar , Hastelloy Polish Bar , Hastelloy Black Round Bar , Hastelloy Forged Bar , Hastelloy Forged

Round Bar , Hastelloy Hex Bar , Forged Hex Bar , Hastelloy Flat Bar , Hastelloy RodApplications

- Petrochemicals Plants

- Oil Refineries

- Fertilizers Plants

- Sugar Mills

- Chemical Plants

- Pharmaceuticals

- Textile Machinery

Manufacturer of Hastelloy Alloy Flanges

Great Metal are providing a subjective scope of Hastelloy Alloy flanges which are accessible in different structures and models. These flanges are accessible in diverse sizes and are in consistence with universal norms. We offer these flanges in different particulars and in this way are requested in both residential and universal markets. We offer these flanges at business sector leading costs.

Specification

Grades Hastelloy C-22, Hastelloy C-276, Hastelloy C-2000 Form Hastelloy Sheet , Hastelloy Coil , Hastelloy Strips , Hastelloy Plates , Hastelloy Circle , Hastelloy Ring Features

- Durability

- Corrosion resistance

- Dimensional accuracy

- High strength

- Chemical resistance

- Excellent finish

Manufacturer of Hastelloy Alloy Buttweld Fittings

Great Metal is occupied with offering a variety of Hastelloy Buttweld Fittings, which is produced from nickel alloy. We additionally offer unmatched scope of Hastelloy Fittings which is created utilizing excellent crude materials and advanced innovation. These are accessible in different particulars that meet the individual prerequisite of our customers. These are offered at industry driving costs. These are kept an eye on different parameters to convey an imperfection unfenced

Specification

Standards ASTM / ASME SB 336 & XXS Grades Hastelloy C-22, Hastelloy C-276, Hastelloy C-2000 Types Bend (Long & Short) , Elbow (180 Deg., 90 Deg. & 45 Deg.) , Tee (Equal & Unequal) , Reducer (Concentric & Eccentric) ,

CAP , Stub end (Long &Short) , Nipple (Barrel)Application

- Petrochemicals Plants

- Chemical Plants

- Industrial Machinery

- Power Industry

- Government Companies

Manufacturer of Hastelloy Alloy Forged Fittings

Great Metal After taking the capable direction of our skilled experts, we offer Hastelloy Forged Fittings. We screen the quality control process with most extreme consideration to convey deformity free products to our customers spread everywhere throughout the world. It is an exactness outlined fitting gathering that unites pipes and tubes guaranteeing zero-spillage and zero remaining stay outs. It guarantees high operational wellbeing at ideal utilization. We exchange these sheltered fitting congregations at a moderate cost.

Specification

Grades Hastelloy C-22, Hastelloy C-276, Hastelloy C-2000 Types

- Hastelloy Union

- Hastelloy Coupling

- Hastelloy Full Coupling

- Hastelloy Cross

- Hastelloy Forged Elbow

- Hastelloy Hex Nipple

- Hastelloy Plug

- Hastelloy Bushing

- Hastelloy Boss

- Hastelloy Insert

- Hastelloy Adapter

- Hastelloy Socket

- Hastelloy Forged Tee

- Hastelloy Olets

- Hastelloy Weldolet

- Hastelloy Sockolet

- Hastelloy Elbowlet

- Hastelloy Thredolet

- Hastelloy Nipolet

- Hastelloy Latrolet

- Hastelloy Sweepolet

- Hastelloy Half Coupling

Manufacturer of Hastelloy Alloy Fasteners

Great Metal has been Sponsored by our top to bottom industry aptitude, we are putting forth a subjective scope of Hastelloy Fasteners to our customers. These are accessible in different determinations that meet the particular prerequisite of our customers. These are exceedingly valued by our customers for the one of a kind components, for example, heartiness, erode safe and superior.

Specification

Grades Hastelloy C-22, Hastelloy C-276, Hastelloy C-2000 Types Bolts Stud Bolts, Hex Head Bolts, Socket Hexagon Head Screw Anchor Bolts, U-Bolts, J Bolts, Mushroom Head Square Neck Bolts , T- Head Bolts , Wing Screw , Eye Bolt , Eye Bolt, Foundation Bolts, Structural Bolts. Features

- Optimum strength

- Corrosion resistance

- Long service life

- Fine finish

-

316 / 316L Sheets & Plates

316 SS is extensively used in marine environments because it is highly resistant to pitting corrosion as compared to other steels.

316 grade steel is typically composed of 18% of chromium & 10% of Nickel. In addition to molybdenum, it also contains other elements in varying concentrations.

Typical Composition of 316 SS:

Chromium: 16% to 18%

Nickel: 10% to 14% max

Molybdenum: 2% & to 3% max

Manganese: 2% max

Silicon: 0.75% max

Nitrogen: 0.1 max

Carbon: 0.08% max

Phosphorus: 0.045% max

Sulfur: 0.030% max

Iron: Balance316L Stainless Steel Sheets have low carbon content & good immunity to sensitization which makes it most suitable for use in heavy gauge welded elements.

Typical composition 316L SS Sheet:

Chromium: 18% max

Nickel: 14% max

Molybdenum: 3% max

Manganese: 2% max

Silicon: 0.75% max

Nitrogen: 0.1 max

Carbon: 0.03% max

Phosphorus: 0.045% max

Sulfur: 0.030% max

Iron: Balance316H SS is the higher carbon version of 316. It is useful for applications requiring elevated temperatures.It has great tensile and yield strength as well as exemplary toughness even at cryogenic temperatures.

316Ti Stainless Steel Sheets contain small amount of titanium typically around 0.5 %. This variant is used for elevated temperature applications due to its high carbon content.The major advantage is it can withstand higher temperature without sensitisation.

Typical composition 316Ti SS Sheet:

Chromium: 18.5% max

Nickel: 13.5% max

Molybdenum: 2.5% max

Manganese: 2% max

Silicon: 1% max

Carbon: 0.08% max

Phosphorus: 0.05% max

Sulfur: 0.03% max

Titanium: 0.40% – 0.70%

Iron: BalanceMechanical Properties:

Grade 316 316L 316Ti Tensile Strength

(MPa) min515 485 515 Yield Strength

0.2% Proof (MPa) min205 170 205 Elongation

(% in 50mm) min40 40 40 – 50 Hardness

Brinell (HB) max217 217 201 316SS sheets are preferred for elevated temperatures applications like welding.

Common Applications:Food processing equipment

Chemical and petrochemical equipment

Brewery & dairy equipment

pharmaceutical production equipment

Coastal architectural paneling

Laboratory equipments

Chemical transportation containers

Boat fittings

Chemical transportation containers

Heat exchangers

Mining screens

Springs, nuts, bolts and screwsWe are one of the most reliable & comprehensive stockholder, supplier & exporter of high quality 316/316L/316Ti stainless steel sheets/plates & coils.

The sheets procured & supplied/exported by us are from the leading mills across the globe

Material Origin:

India,Europe,Korea, United States, Thailand, Taiwan, JapanManufacturers:

Acerinox, Aperam, Bahru, Baosteel, DKC, Jindal, Nippon, Outokumpu, POSCO, SAIL,

Thyssenkrupp.We are able to supply cut to size 316/316L/316Ti SS sheets & plates (as per your specifications) in any quantities with all the necessary mill test reports.

316 STAINLESS STEEL SHEETS/PLATES/COILS SPECIFICATIONS:

Standard: ASTM A240

Surface Finish: 2B, 2D, BA, HL, No.4

Size Ranges :Sheets:

Thickness: 0.25mm ~ 6.0mm

Width: 600mm ~ 2000mm

Length: 1000mm ~ 10000mmPlates:

Thickness: 3mm to 100mm

Width: 1000mm to 3000mm

Length: 2438 mm / 3048mm / 6098 mm to 12500 mmCoils:

Thickness: 0.31mm ~ 12.7mm

Width: 1000mm / 1120mm / 1250 / 1525mm / 2000mm

Length: as per your requirement.*(Cut to sizes available as per your requirement.)

Types: Flat bars,Strips,Circle, Ring, Profile

-

SS304 / 304L Sheets & Plates

Typical Composition:

Chromium:17.5–20%

Nickel:8–11%

Manganese:2% max

Silicon:1% max

Phosphorus:0.045% max

Sulfur:0.03% max

Carbon:0.08% max304L Stainless Steel Sheets

It has similar composition except the carbon content which is less than 0.03 %.It has excellent formability and ease of fabrication.Due to its improved weldability it is used in heavy gauge components.

Mechanical Properties:Grade 304 304L Tensile Strength

(MPa) min515 485 Yield Strength

0.2% Proof(MPa) min205 170 Elongation

(% in 50.8mm) min40 40 Hardness

Brinell (HB) max201 201 304 SS sheets are used in various home & commercial application. The sheets offer good corrosion resistance to many industrial environment & chemical corrodents.

Common Applications:

Tanks & Containers

Food processing equipment (Wine making, dairy equipment etc)

Domestic tools (sinks, stoves, tabletops, Refrigerators etc)

Architectural Panels

Heat Exchangers

Dyeing Industry

Springs, Nuts, Bolts & ScrewsWe are one of the most reliable & comprehensive stockholder, supplier & exporter of high quality 304 SS Sheets, 304L SS Sheets, Plates & Coils.

The sheets procured & supplied/exported by us are from the leading mills across the globe.

Material Origin:

India,Europe,Korea, United States, Thailand, Taiwan, JapanManufacturers:

Acerinox, Aperam, Bahru, Baosteel, DKC, Jindal, Nippon, Outokumpu, POSCO, SAIL,

Thyssenkrupp.We are able to supply cut to size 304/304L SS sheets & plates (as per your specifications) in any quantities with all the necessary mill test reports.

304 STAINLESS STEEL SHEETS/PLATES/COILS SPECIFICATIONS:

Standard: ASTM A240

Surface Finish: 2B, 2D, BA, HL, No.4

Size Ranges :Sheets:

Thickness: 0.25mm ~ 6.0mm

Width: 600mm ~ 2000mm

Length: 1000mm ~ 10000mmPlates:

Thickness: 3mm to 100mm

Width: 1000mm to 3000mm

Length: 2438 mm / 3048mm / 6098 mm to 12500 mmCoils:

Thickness: 0.31mm ~ 12.7mm

Width: 1000mm / 1120mm / 1250 / 1525mm / 2000mm

Length: as per your requirement.*(Cut to sizes available as per your requirement.)

Types: Flat bars,Strips,Circle, Ring, Profile

-

310 / 310S Sheets & Plates

Typical Composition:

Chromium:24-26%

Nickel:19-22%

Manganese:2% max

Silicon:1.5% max

Phosphorus:0.045% max

Sulfur:0.03% max

Carbon:0.25% max310S Stainless Steel Sheets / Plates / Coils

310S SS is the low carbon variant of the 310 SS.

It is used for ease of fabrication & it is less susceptible to embrittlement and sensitization.Typical Composition:

Chromium:24-26%

Nickel:19-22%

Manganese:2% max

Silicon:1.5% max

Phosphorus:0.045% max

Sulfur:0.03% max

Carbon:0.08% max

Mechanical Properties:Grade 310 / 310S Tensile Strength

(MPa) min520 Yield Strength

0.2% Proof(MPa) min205 Elongation

(% in 50.8mm) min40 Hardness

Brinell (HB)max225 They are extensively used in moderate carburising environments such as petrochemical industries.

Common Applications:

-Cryogenic structures

-Kilns

-Heat Exchangers

-Radiant Tubes

-Tube hangers for steam boilers & petroleum refining

-Coal gasifier internal components

-Steel Plants- continuous casting equipment,smelter & steel melting apparatus

-Furnace parts- burners, doors, piping & recuperators.We are one of the most reliable & comprehensive stockholder, supplier & exporter of high quality 310 SS Sheets, 310S SS Sheets, Plates & Coils.

The sheets procured & supplied/exported by us are from the leading mills across the globe.

Material Origin:

India,Europe,Korea, United States, Thailand, Taiwan, JapanManufacturers:

Acerinox, Aperam, Bahru, Baosteel, DKC, Jindal, Nippon, Outokumpu, POSCO, SAIL,

Thyssenkrupp.We are able to supply cut to size 310/310S SS sheets & plates (as per your specifications) in any quantities with all the necessary mill test reports.

310 STAINLESS STEEL SHEETS/PLATES/COILS SPECIFICATIONS:

Standard: ASTM A240

Surface Finish: 2B, 2D, BA, HL, No.4

Size Ranges :Sheets:

Thickness: 0.25mm ~ 6.0mm

Width: 600mm ~ 2000mm

Length: 1000mm ~ 10000mmPlates:

Thickness: 3mm to 100mm

Width: 1000mm to 3000mm

Length: 2438 mm / 3048mm / 6098 mm to 12500 mmCoils:

Thickness: 0.31mm ~ 12.7mm

Width: 1000mm / 1120mm / 1250 / 1525mm / 2000mm

Length: as per your requirement.*(Cut to sizes available as per your requirement.)

Types: Flat bars,Strips,Circle, Ring, Profile

-

410 Sheet & Plates

Typical Composition:

Chromium: 11.5-13.5%,

Nickel: 0.75%,

Manganese: 1% max

Silicon: 1% max

Carbon: 0.15% max

Phosphorus: 0.040% max

Sulfur: 0.030%. maxMechanical Properties:

Grade 410 Tensile Strength

(MPa) min517 Yield Strength

0.2% Proof(MPa) min310 Elongation

(% in 50.8mm) min25 Hardness

Rockwell (Max)B80 410 SS steel is ideal for application requiring average corrosive resistance & good mechanical properties. It is frequently used in following applications.

Common Applications:

Pump, valves & shafts

Gas turbines

Steam Turbines

Nozzles

Nuts, bolts, screws & bushings

Surgical Instruments

Kitchen Utensils

Mine ladder rugs

CutleryWe are one of the most reliable & comprehensive stockholder, supplier & exporter of high quality 410 Stainless Steel Sheets, Plates & Coils.

The 410 sheets, plates, coils procured & supplied/exported by us are from the leading mills across the globe.

Material Origin:

India,Europe,Korea, United States, Thailand, Taiwan, JapanManufacturers:

Acerinox, Aperam, Bahru, Baosteel, DKC, Jindal, Nippon, Outokumpu, POSCO, SAIL,

Thyssenkrupp.We are able to supply cut to size 410 SS sheets & plates (as per your specifications) in any quantities with all the necessary mill test reportss.

410 STAINLESS STEEL SHEETS/PLATES/COILS SPECIFICATIONS:

Standard: ASTM A240

Surface Finish: 2B, 2D, BA, HL, No.4

Size Ranges :Sheets:

Thickness: 0.25mm ~ 6.0mm

Width: 600mm ~ 2000mm

Length: 1000mm ~ 10000mmPlates:

Thickness: 3mm to 100mm

Width: 1000mm to 3000mm

Length: 2438 mm / 3048mm / 6098 mm to 12500 mmCoils:

Thickness: 0.31mm ~ 12.7mm

Width: 1000mm / 1120mm / 1250 / 1525mm / 2000mm

Length: as per your requirement.*(Cut to sizes available as per your requirement.)

Types: Flat bars,Strips,Circle, Ring, Profile

-

Inconel Alloys

Properties

Inconel alloys are oxidation- and corrosion-resistant materials well suited for service in extreme environments subjected to high pressure and kinetic energy. When heated, Inconel forms a thick and stable passivating oxide layer protecting the surface from further attack. Inconel retains strength over a wide temperature range, attractive for high-temperature applications where aluminium and steel would succumb to creep as a result of thermally induced crystal vacancies (see Arrhenius equation). Inconel’s high temperature strength is developed by solid solution strengthening or precipitation strengthening, depending on the alloy. In age-hardening or precipitation-strengthening varieties, small amounts of niobium combine with nickel to form the intermetallic compound Ni3Nb or gamma prime (γ’). Gamma prime forms small cubic crystals that inhibit slip and creep effectively at elevated temperatures. The formation of gamma-prime crystals increases over time, especially after three hours of a heat exposure of 850 °C, and continues to grow after 72 hours of exposure.

Manufacturer of Inconel Alloy Rods, Bars & Wires

Calico Metal has Inconel which is a nickel-chromium alloy utilized for applications that require erosion and high temperature resistance. This nickel alloy was intended for service temperatures from cryogenic to elevated temperatures in the scope of 2000° F. It is non-attractive, has fantastic mechanical properties, and presents the alluring blend of high quality and great weldability under an extensive variety of temperatures

Specification

Standard ASTM, ASME, API, AISI, BS, ANSI, DIN, JIS, MSSP, NACE Grades Inconel 600, Inconel 601, Inconel 625, Inconel 625LCF, Inconel 686, Inconel 718, Inconel 800, Inconel 825, Inconel X-750 Size 1mm to 200mm diameter Type Bars, Rods, wire Manufacturer of Inconel Alloy Plates & Sheets

Calico Metal offer an extensive variety of Inconel Sheets and Plates. These top quality Inconel Sheets and Plates are broadly prescribed for their high resistance to destructive medium, warmth and anxiety consumption splitting. Our plates are generally utilized as a part of different designing and modern ventures. These Inconel Plates can be modified according to our customers’ required details.

Specification

Standard ASTM / ASME SB 168, ASTM / ASME SB 424 , ASTM / ASME SB 443 Grades Inconel 600, Inconel 601, Inconel 625, Inconel 625LCF, Inconel 686, Inconel 718, Inconel 800, Inconel 825, Inconel X-750 Value Added Service

- Heat treatment

- Annealed & pickling

- Rolling, cutting, bending, forging, minor fabrication, etc.

Manufacturer of Inconel Alloy Pipes & Tubes

Calico Metal broadens a subjective scope of Inconel Pipes to our customers that is fabricated in consistence with set industry standards. These pipe fittings are made in accordance with the different needs of commercial ventures and are given to them at very high rates. It is highly dependable and shows phenomenal resistance to consumption.

Specification

Grades Inconel 600, Inconel 601, Inconel 625, Inconel 625LCF, Inconel 686, Inconel 718, Inconel 800, Inconel 825, Inconel X-750 Types Seamless / ERW / Welded/ Fabricated Range 15 NB up to 600 NB in SCH 5S, 10S, 10, 20, 40S, 40, STD, 60, 80S, 80, XS, 100, 120, 140, 160 & XXS Form Round, Square, Rectangular, Hydraulic etc. Length Single Random, Double Random & Cut Length End Plain End, Beveled End, Threaded Applications

- Petrochemicals Plants

- Oil Refineries

- Fertilizers Plants

- Sugar Mills

- Chemical Plants

- Pharmaceuticals

- Textile Machinery

Manufacturer of Inconel Alloy Flanges

Calico Metal give the clients an incredible quality scope of Inconel Flanges, which are made from high review quality crude materials. These Inconel Flanges can be customise according to our valuable clients details. These Inconel Flanges are broadly known for its toughness and quality. Our Inconel Flanges can be profited at industrial driving cost.

Specification

Standard ANSI/ASME B16.5, ANSI B16.47 API, DIN, JIS, BS Grades Inconel 600, Inconel 601, Inconel 625, Inconel 625LCF, Inconel 686, Inconel 718, Inconel 800, Inconel 825, Inconel X-750 Size 1/2 inch – 48 inch (15mm – 1200mm) Types Socket Weld, Slip On, Blind, Lapped, Screwed, Weld Neck, Long Weld Neck, Reducing, Spectacle, Ring Joint Features

- Durability

- Corrosion resistance

- Dimensional accuracy

- High strength

- Excellent finish

Manufacturer of Inconel Alloy Buttweld Fittings

Calico Metal has produced from diverse grades of Inconel, these fittings find broad application crosswise over different commercial industries. Our scope of buttweld fittings incorporate elbow 90 deg, elbow 45 deg, elbows 180 deg, diminishing elbow, tees, crosses and concentric/unusual reducers. Accessible in diverse determinations, we offer these buttweld fittings at the most competitive costs.

Specification

Grades Inconel 600, Inconel 601, Inconel 625, Inconel 625LCF, Inconel 686, Inconel 718, Inconel 800, Inconel 825, Inconel X-750 Range 15 NB UP TO 600 NB IN SCH 5S, 10S,10, 20, 40S, 40, STD, 60, 80S, 80, XS, 100, 120, 140, 160 & XXS Types Elbow 90 Deg, Elbow 45 Deg, Elbow 180 Deg, long/short radius elbows, equal/unequal tees, concentric/eccentric reducers, caps, crosses, short/long neck stub-ends Application

- Petrochemicals Plants

- Chemical Plants

- Industrial Machinery

- Power Industry

- Government Companies

Manufacturer of Inconel Alloy Forged Fittings

Calico Metal offers an extensive variety of Inconel Forged Fittings that are produced from quality quality checked & tested components. Known for its amazing and solidness, these inconel fittings are generally utilized as a part of different commercial industries over the globe.

Specification

Standards ASTM / ASME SB 564 Grades Inconel 600, Inconel 601, Inconel 625, Inconel 625LCF, Inconel 686, Inconel 718, Inconel 800, Inconel 825, Inconel X-750 Types • Elbow – 90 Deg. & 45 Deg

• Tee – Equal & Reducing

• Union, Cross, Coupling – Full & Half

• Socket Reducing, CAP, Plug-Hex & Square, Nipples (Hex/Reducing), Bushing, Sockolet, Weldolet, Thredolet, Elbolet, NipoletApplication

- Petrochemicals Plants

- Chemical Plants

- Industrial Machinery

- Power Industry

- Government Companies

Manufacturer of Inconel Alloy Fasteners

Calico Metal has extensive variety of inconel fasteners includes high mechanical quality, close dimensional resilience and superb wrapping up. These fasteners are straightforward for simple establishment and evacuation. We offer a complete arrangement of clasp including stud screws, hex fasteners, square screws, hex nuts, t-head fasteners and so on. Accessible in diverse evaluations of inconel with changing measurements at the most competitive costs.

Specification

Standard ASTM / ASME SB 163 / 167 / 517 / 704 / 705 Grades Inconel 600, Inconel 601, Inconel 625, Inconel 625LCF, Inconel 686, Inconel 718, Inconel 800, Inconel 825, Inconel X-750 Types Bolts Stud Bolts, Hex Head Bolts, Socket Hexagon Head Screw Anchor Bolts, U-Bolts, J Bolts, Mushroom Head Square Neck Bolts , T- Head Bolts , Wing Screw , Eye Bolt , Eye Bolt, Foundation Bolts, Structural Bolts. Features

- Optimum strength

- Corrosion resistance

- Long service life

- Fine finish

-

Duplex & Super Duplex Flanges

There is a great connectivity to pipes in Super Duplex flanges they have long life in the applications having low to high pressure like refinery industry. Their corrosion resistance levels are also very high and therefore they are well preferred in the chemical and marine industries. The Duplex & Super Duplex Flanges are exceptionally useful for the applications such as:

- Equipments of oil and gas industry.

- Offshore oil production

- Equipment of pulp and paper mill

- Desalination plants

- Marine applications

- Structural and mechanical equipments

- Heat exchangers

- Power industry

- High pressure seawater piping and RO plants

- Fire fighting systems

RANGE :

1/2″ NB TO 48″NB.QUALITY :

DUPLEX & SUPER DUPLEX STEEL

UNS S31803, S32205 (2205),S32750 (2507), S32760 (Z-100)

S32900 (329), S32304, F-51, F-53, F-54, F-55 & F-60 & HIGH NICKEL ALLOYSFORM :

Duplex and Super Duplex Weldneck, Duplex and Super Duplex Slipon, Duplex and Super Duplex Blind, Duplex and Super Duplex Socket Weld, Duplex and Super Duplex Lap Joint, Duplex and Super Duplex Spectacles, Duplex and Super Duplex Ringjoint, Duplex and Super Duplex Orifcase, Duplex and Super Duplex Long Weldneck, Duplex and Super Duplex Deck Flange, etc.NACE :

MR 01-75, MR 01 03CLASS :

150#, 300#,400 #,600#,900#, 1500# & 2500 #.VALUE ADDED SERVICES :

- Annealed

- Anodising

- Casting

- Centreless Grinding (CG)

- Drilling

- Electroplating

- Forging

- Heat Treatment (Hardening & Tempering)

- Machining (CNC)

- Pickled

- Polish (Electro & Commercial)

- Threading (As per Guage)

- Welding

TEST CERTIFICATION :

Our Materials Are Tested To Relevant Standard And Wherever Possible We Give Original / Copy Of Test Certificate With Heat Number As Well As Govt. Approved Laboratories Test Certificate Can Also Be Provided. We Supply the Material under Inspection of Any Third Party Inspection Agency as per the Client’s Requirements Such As :

1) Bv- Bureau VERITAS Industrial Services (India) Pvt. Ltd

2) Lloyds Inspection Agency

3) Rina

4) Irs – International Register Of Shipping (Irs)

5) Dnv – Det Norske Veritas

6) Tcs – Tata Consultancy Services

7) Tuv India -

Flanges

ASME/ANSI B16.5 :

WELDING NECK FLANGE, SLIP-ON FLANGE, BLIND FLANGE,HIGH HUB BLIND FLANGE, SOCKET WELD FLANGE, LAPJOINT FLANGE, THREADED FLANGE, RING TYPE JOINT FLANGE.

Pressure Class : 150, 300, 400 , 600 , 900, 1500 , 2500» ASME/ANSI B16.47 :

WELDING NECK FLANGE, BLIND FLANGE. (SERIES A & B)

Pressure Class : 75, 150, 300, 400 , 600 , 900» ASME/ANSI B16.36 :

(ORIFICE FLANGES) WELDING NECK FLANGE, SLIPON FLANGE, THREADED FLANGE.

Pressure Class : 300, 400 , 600 , 900, 1500 , 2500» ASME/ANSI B16.36 :

(ORIFICE FLANGES) WELDING NECK FLANGE, SLIPON FLANGE, THREADED FLANGE.

Pressure Class : 300, 400 , 600 , 900, 1500 , 2500» ASTM/ANSI B16.48:( Figure-8 blanks) :

Pressure Class : 150, 300, 400 , 600 , 900,1500, 2500

» MSS SP44 :

WELDING NECK FLANGE, BLIND FLANGE.

Pressure Class :300, 400 , 600 , 900» API 6A :

WELDING NECK FLANGE, THREAD FLANGE,BLIND FLANGE.

Pressure : 2000Psi, 3000Psi, 5000Psi, 10000Psi, 15000Psi, 20000Psi, 25000Psi» Material :

ASTM A105; ASTM A350, A694 F42/F46/F52/F60/F65

ASTM A182 F304/304L,F316/316L, F321, F310,

ASTM A 182 F51/F53/F55» Size : 1/2″-48″

Calicol metal is one of the leading manufacturers and exporters of Steel Flanges. Our proficient and skilled team is specialized in manufacturing durable range of Steel Flanges which are available at reasonable rates. Steel Flanges manufactured at our unit using superior quality steel. The Steel Flanges are popular for their rust resistance and robustness. Steel Flanges for the clientele are made available in regular and custom-made specification. Hence we are one of the highly sought after Steel Flanges manufacturer in India.

Features:

- Anti oxidization

- Excellent performance

- Resilient

- Superior tensile strength

- Reliable

- Excellent quality

-

304 sheet / 316 sheet

Incoloy Availability

Calico Metal supplies 304 sheet / 316 sheet and 316 in the form of plate, sheet, strip, bar, wire, pipe, tubing, pipe fittings, and flanges.

What are the Characteristics of Incoloy?

- Good corrosion resistance in aqueous environments

- Excellent strength resistance in high-temperature settings

- Excellent oxidation and carburization resistance in high-temperature settings

- Good creep-rupture strength

- Ease of fabrication

-

420 Sheets & Plates

Typical Composition:

Chromium: 12-14%,

Manganese: 1% max

Silicon: 1% max

Carbon: 0.15% max

Phosphorus: 0.040% max

Sulfur: 0.030% maxMechanical Properties:

Grade 420 Tensile Strength

(MPa) min586 Yield Strength

0.2% Proof(MPa) min276 Elongation

(% in 50.8mm) min25 Hardness

Brinell (HB)max241 420 SS is used in numerous applications, generally preferred in household purposes

Common Applications:

Surgical instruments

Needle valves

Knife blades

Cutlery

Scissors

Shear bladeWe are one of the most reliable & comprehensive stockholder, supplier & exporter of high quality 420 Stainless Steel Sheets, Plates & Coils.

The sheets procured & supplied/exported by us are from the leading mills across the globe.

Material Origin:

India,Europe,Korea, United States, Thailand, Taiwan, Japan420 STAINLESS STEEL SHEETS/PLATES/COILS SPECIFICATIONS:

Standard: ASTM A240

Surface Finish: 2B, 2D, BA, HL, No.4

Size Ranges :Sheets:

Thickness: 0.25mm ~ 6.0mm

Width: 600mm ~ 2000mm

Length: 1000mm ~ 10000mmPlates:

Thickness: 3mm to 100mm

Width: 1000mm to 3000mm

Length: 2438 mm / 3048mm / 6098 mm to 12500 mmCoils:

Thickness: 0.31mm ~ 12.7mm

Width: 1000mm / 1120mm / 1250 / 1525mm / 2000mm

Length: as per your requirement.*(Cut to sizes available as per your requirement.)

Types: Flat bars,Strips,Circle, Ring, Profile

-

308 / 308S Sheets & Plates

Typical Composition:

Iron:66%

Chromium: 20%

Nickel:11%

Manganese: 2%

Silicon:1%

Carbon: 0.080%

Phosphorus:0.045%

Sulfur:0.030%Mechanical Properties:

Grade 308 Tensile Strength

(MPa) min585 Yield Strength

0.2% Proof(MPa) min240 Elongation

(% in 50mm) min50 Hardness

Brinell (HB) max139 It’s commonly used as filler metal while welding 304 SS.

Common Applications:Restaurant and distillery equipment,

In manufacturing of welding wire,

Chemical tanksWe are one of the most reliable & comprehensive stockholder, supplier & exporter of high quality 308 SS Sheets, Plates & Coils.

The sheets procured & supplied/exported by us are from the leading mills across the globe.

Material Origin:

India,Europe,Korea, United States, Thailand, Taiwan, JapanManufacturers:

Acerinox, Aperam, Bahru, Baosteel, DKC, Jindal, Nippon, Outokumpu, POSCO, SAIL,

Thyssenkrupp.We are able to supply cut to size 308 Stainless Steel sheets & Plates/Coils (as per your specifications) in any quantities with all the necessary mill test reports.

308 STAINLESS STEEL SHEETS/PLATES/COILS SPECIFICATIONS:

Standard: ASTM A240

Surface Finish: 2B, 2D, BA, HL, No.4

Size Ranges :Sheets:

Thickness: 0.25mm ~ 6.0mm

Width: 600mm ~ 2000mm

Length: 1000mm ~ 10000mmPlates:

Thickness: 3mm to 100mm

Width: 1000mm to 3000mm

Length: 2438 mm / 3048mm / 6098 mm to 12500 mmCoils:

Thickness: 0.31mm ~ 12.7mm

Width: 1000mm / 1120mm / 1250 / 1525mm / 2000mm

Length: as per your requirement.*(Cut to sizes available as per your requirement.)

Types: Flat bars,Strips,Circle, Ring, Profile

- +91-79 -2278 0000

-

info@calicometals.in/kapil.gandhi@calicometals.in

info@calicometals.in/kapil.gandhi@calicometals.in